A Broken Nuova Simonelli Oscar Espresso Machine

I’ve been wanting an espresso machine for a very long time, but I’ve never really put in a whole lot of effort to find a decent and reasonably priced one. A friend of mine who’s done way more research than I ever would recommended a few. Specifically, he has a Nuova Simonelli Oscar that he bought used for a good price many years ago. He chose this one because it was the cheapest he could find that was NSF rated. All of the parts are designed to be replaced and repaired, so it’s a good bridge between the consumer and professional models.

He found his same model on eBay for about $300 after we had talked about it. The listing indicated that this machine had some issues with intermittent pressure and they were selling it as-is / parts only. I decided to place a bid on it because I figured I could fix it and replace whatever was necessary. For the price of my time and labor and a few extra parts, I figured I could get a decent machine for little comparative cost and learn some pretty interesting stuff in the process.

As usual, the process to fix it wasn’t as easy as it initially seemed. In fact, at the time of this writing it’s still not fully operational.

Investigation and Troubleshooting

Upon receipt of the espresso machine I noticed that it had been packed with only one layer of styrofoam on one side of the box, with everything else pretty much exposed. It was wrapped in a layer of a thin foam that seemed to provide little protection. It was immediately apparently that it had been damaged in shipping. Further, all of the metal pipes and the steam valve were really gross and needed some serious cleaning.

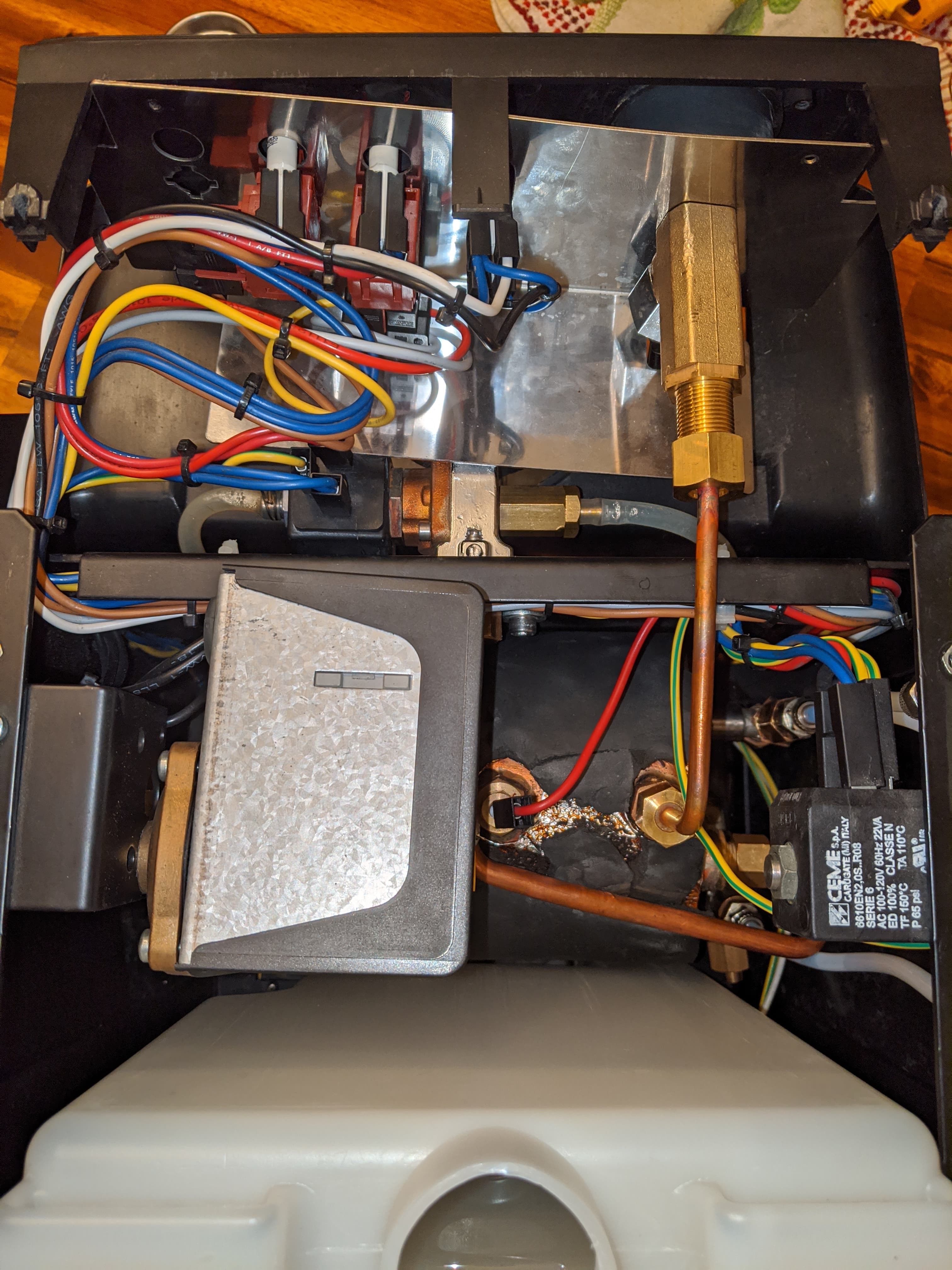

The front panel assembly was pushed back entirely from the frame. I removed the top and saw that the pipe connecting the steam output to the valve assembly was mangled beyond repair.

Fortunately this was pretty straightforward to replace and easy to diagnose, so I looked around at what else might be an issue. The listing said that it had issues with intermittent pressue, so I figured that this was due to one or more of the following problems:

- Really dirty pipes preventing proper flow

- Heating element was acting up

- Water level probe wasn’t working correctly

Additionally, before I disassembled the boiler I decided to pull a quick shot to see if there was anything that had actually failed, and to check the temperature of the output water. After some fiddling around - the heating element didn’t seem to be connected properly or something (??) - I was able to convince the machine to heat the water. The steam valve output steam as it should have, at least. I connected up my portafilter (I’m terrible with espresso terminology) and pulled some water through while measuring the temperature with a probe. I figured the cool bare metal would cool the water as it passed through, but by the time it reached my probe just at the output, it was around 145 F - which I’m pretty sure was too cool.

I found a website with a wonderful troubleshooting guide on this machine that was super useful to learning how the components interacted with each other. Without it I would have had an extra tough time diagnosing the issues with this.

Ultimately, it seemed that with the exception of the mangled pipe, the key problem with this machine was its cleanliness. In any case, that was where I needed to start.

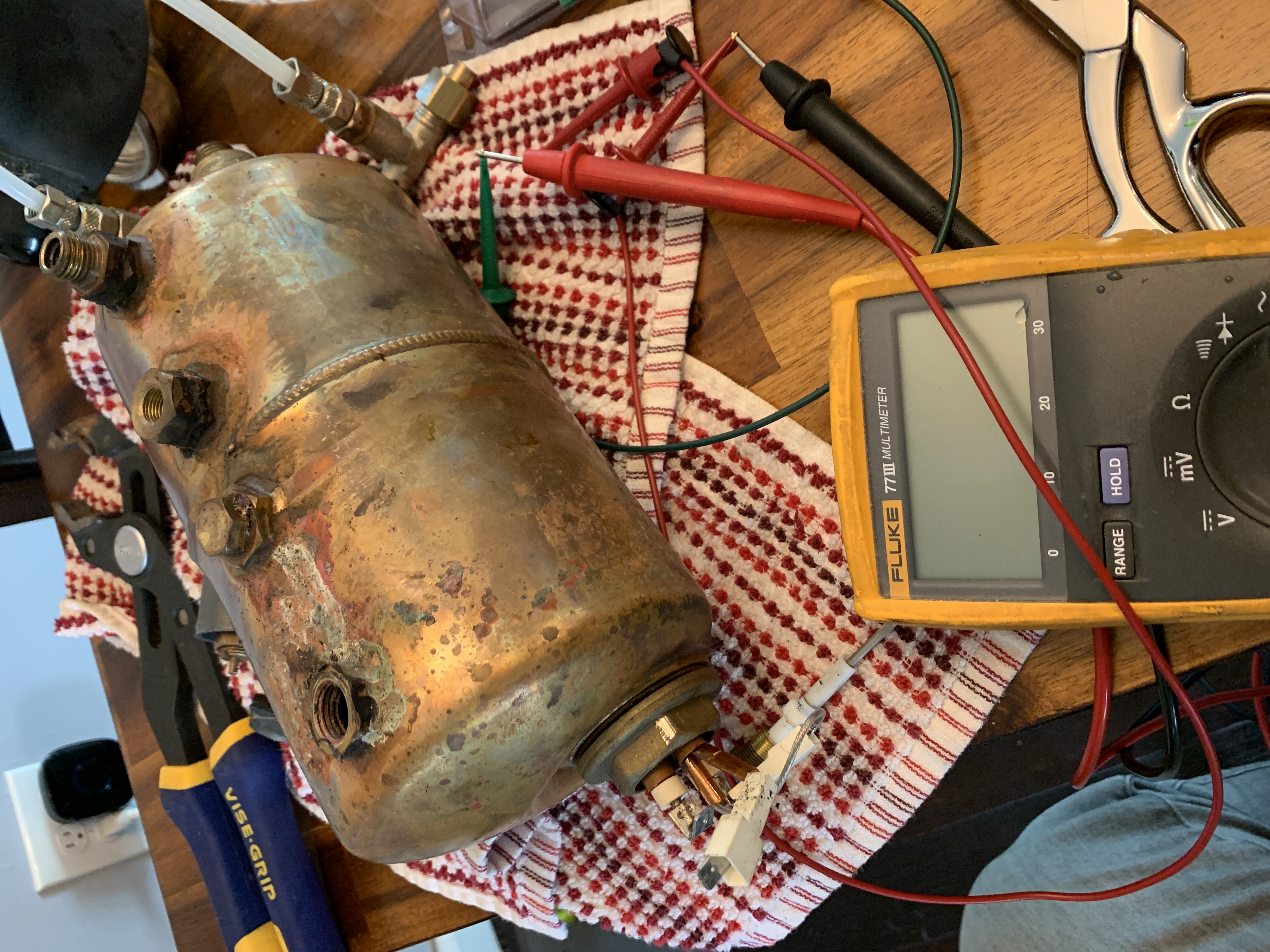

Cleaning

The cleaning process was pretty simple. I basically just disassembled the machine as much as possible and soaked everything in a citric acid solution. The change was immediate and pretty incredible. Everything cleaned up really nicely.

I then reassembled the machine.

Reassembly

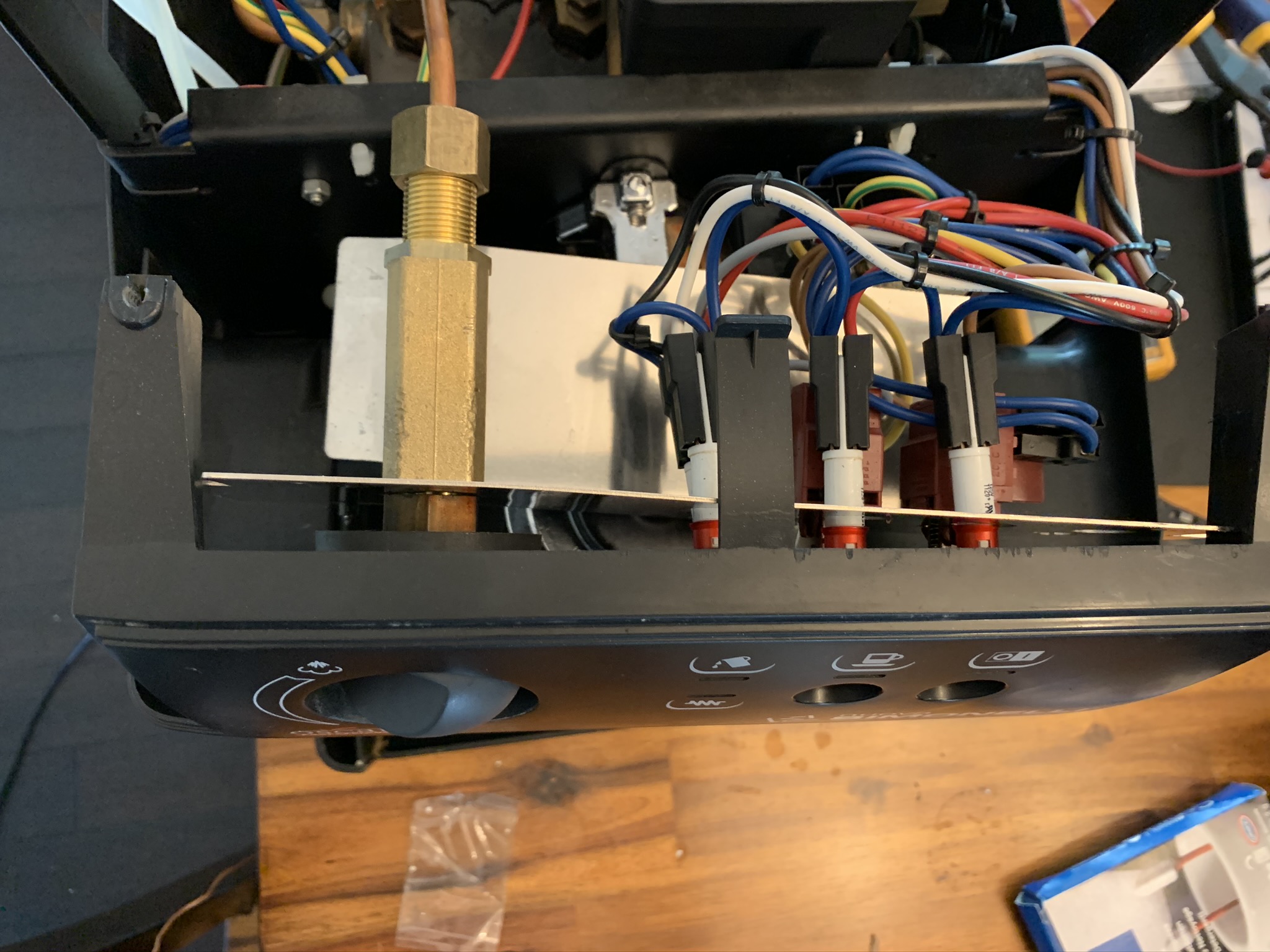

After I received my replacement pipe I put everything back together, and even had no extra parts! Unfortunately, for some reason I haven’t been able to figure out quite yet, the front panel didn’t go back together cleanly.

It seems that in addition to the pipe getting bent, the boiler itself or some of the other pipes seemed to become twisted as well. Unfortunately espressoparts doesn’t seem to have listings for those pipes so I need to email them and ask - or build my own pipes. At first glance it looks like the pipe they sent me needs to be about 1 cm longer or so. However, the rest of the components kind of went back together a little out of alignment as well, so I’m not sure.

In the image above, it’s plain to see that the front panel is pretty well bent. I could simply try to screw the panel in and force it all to fit, but I think that would put too much strain on the plastic casing. A lot of the posts were damaged as well, which has really compromised its integrity anyway. It appears that the machine should fit together nicely, so it’s clear something is still wrong.

My plan is to disassemble it again and maybe more carefully put it back together. I think I need to replace another pipe or two… At the very least, shots pull nicely and at a good temperature in its current state, so at least mechanically it’s pretty sound.

Conclusion

At this point I emailed the seller of the machine and asked for a refund, because while I knew the machine was broken - the packaging and state upon receipt was a lot worse than I think was reasonable. They were super easy to work with, and I kind of feel bad about how this turned out, but at the same time this has been a major chore.

I still have more work to do.